Project Objectives

The FORMAT project aims at developing an innovative Forecasting Methodology supporting decision making in Manufacturing Industries.

A business process can be considered as a technical system able to generate value by manufacturing products (or delivering services) under certain boundary conditions, such as market demand, raw material availability and product requirements. When the process is not able to exploit the available resources according to their potentialities, its capability to survive market competition decreases dramatically, due to a disadvantageous balance between benefits provided and involved costs. Many methods for Business Process Re-engineering (BPR) have been suggested in the last years to address the redesigning and innovation of business and manufacturing systems and the Total Quality Management (TQM) is used to manage the cost of the system according to the quality requirements. Generally speaking, identifying value bottlenecks of a process means recognizing new productivity requirements, functionality performance to be enhanced, new functions to be fulfilled, new properties or features of the system. The implementation of suitable technical solutions able to cover these deficiencies is a difficult task: actually, it involves the knowledge dispersed across different disciplines, including process engineering, resources management, information technology and marketing.

Within this context the analysis of the emerging technologies and their potential impact on markets, economies and societies requires reliable and repeatable methods and tools since the related information plays a critical role for strategic decisions of private and public organizations.

Therefore it is not surprising that more than fifty methodologies with different characteristics and specific purposes have been proposed so far in this field. Nevertheless all these techniques reveal several weaknesses such as limited accuracy on mid and long-term forecast; poor repeatability; poor adaptability, i.e. no universal methods are known, besides complementary instruments must be integrated according to the specific goals and data availability.

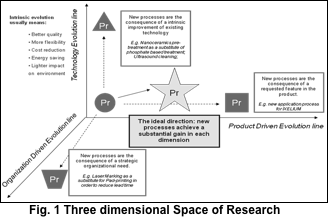

These considerations highlight the need to introduce structured methods and tools capable to support strategic decisions in industrial R&D activities, by managing the multi-disciplinary complexity of the current systems and by anticipating the future characteristics of products and processesaccording to a 3D perspective represented in the following figure:

1. A PRODUCT PERSPECTIVE

- Which will be the requirements of the next generation of products capable to satisfy a given market need?

- Which will be the features these products will have in order to fulfil these requirements?

2. A TECHNOLOGY PERSPECTIVE

- Which technologies will attain the leanest, high quality and most efficient process to produce such products?

- How will the manufacturing processes be structured to embed these technologies in the most effective way?

3. AN ORGANIZATIONAL PERSPECTIVE

- Which organizational demands will impact on the definition of next-generation products and processes?

- How to classify selection criteria and physical/technological constraints according to an organizational perspective?

The FORMAT project aims at developing of an innovative forecasting methodology supporting decision making in Manufacturing Industries, facing and answering the 3 previous perspectives:

- Product Evolution: the design of new products can require new process technologies for the product itself to be manufactured.

- Technological Evolution is the technological pressure, intrinsic technological evolution leads to changes and improvements in the manufacturing processes that must not be let unexplored.

- Organizational Evolution: to fulfill some industrial strategies, new processes with improved performance can be necessary.

The ideal direction to be pursued in developing the FORMAT innovative forecasting methodology is that new processes in Manufacturing Industries achieve a substantial gain in each dimension.

In the current common approach for White Good Industry and, generally in the manufacturing sector, manufacturing is involved at different stages of product development. Although the principle of “the sooner the better” is widely accepted, very often manufacturing is unprepared to address product driven technological changes due to limited resources to be dedicated to R&D of manufacturing processes. So there are other two industrial needs:

- to anticipate as much as possible the research and development of process technologies so as to eliminate uncertainties, infancy problems and related costs, and to better exploit competitive advantages in an aggressive market such as the White Goods one.

- to focus R&D resources on those technologies, which are the most promising along the above-mentioned three axes of evolution.

The final result of the project will be the development of an innovative Forecasting Methodology, backed by a web semantic IT tool, supporting decision making in Manufacturing Industries.